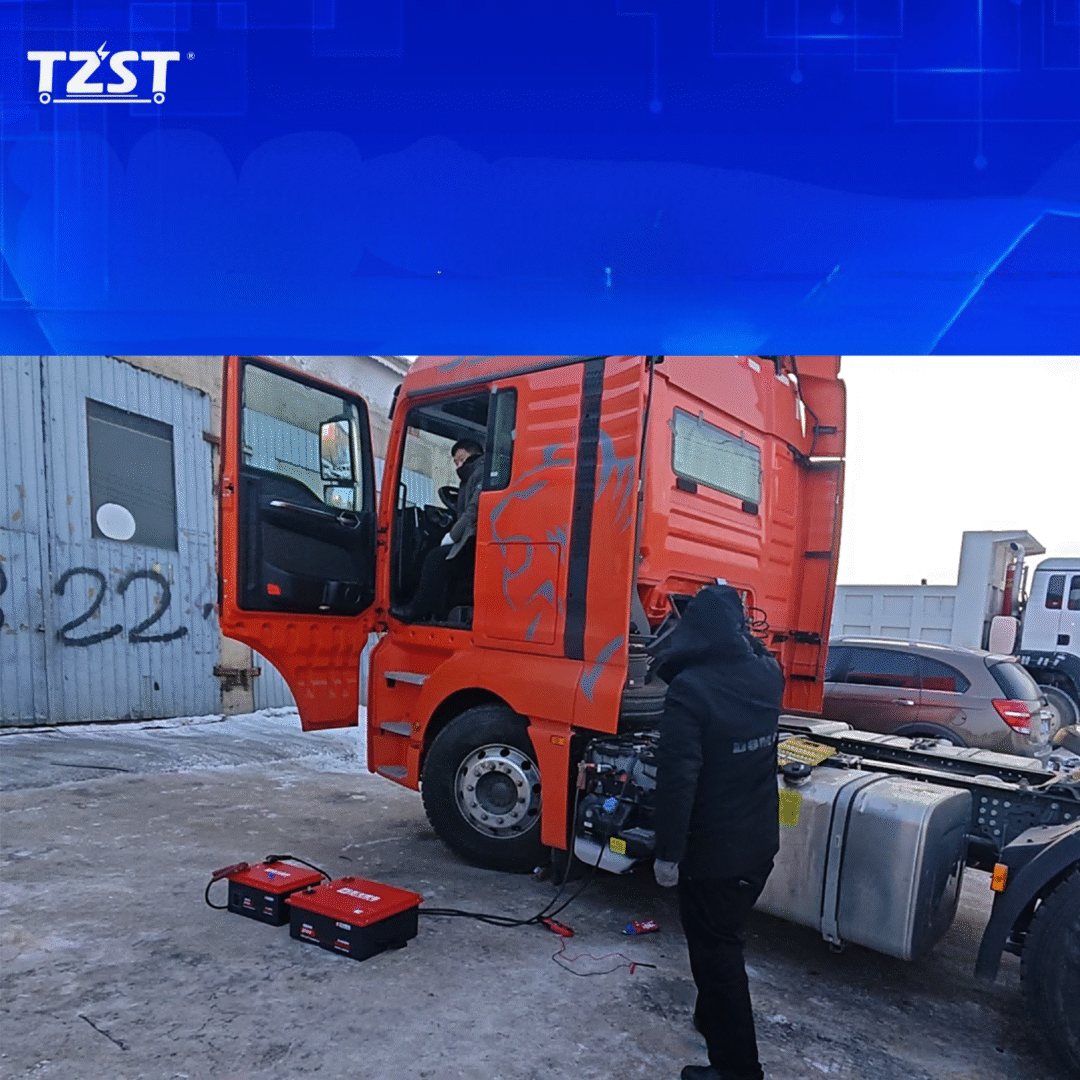

In the morning light of a logistics park in Northeast China, Master Zhang’s diesel heavy truck had failed to ignite three times in a row. The low temperature of minus 25 degrees Celsius caused the lead-acid battery to completely “strike”, putting fresh goods worth 10,000 yuan at risk. This scene occurs over 3 million times across the country every winter, exposing the fatal flaws of traditional lead-acid batteries in the commercial vehicle field. As the industry focuses its attention on the new energy passenger car track, TZST Lithium Battery is using its twenty years of technology accumulation to set off a silent revolution in the Heavy-Duty Truck Starting Battery.

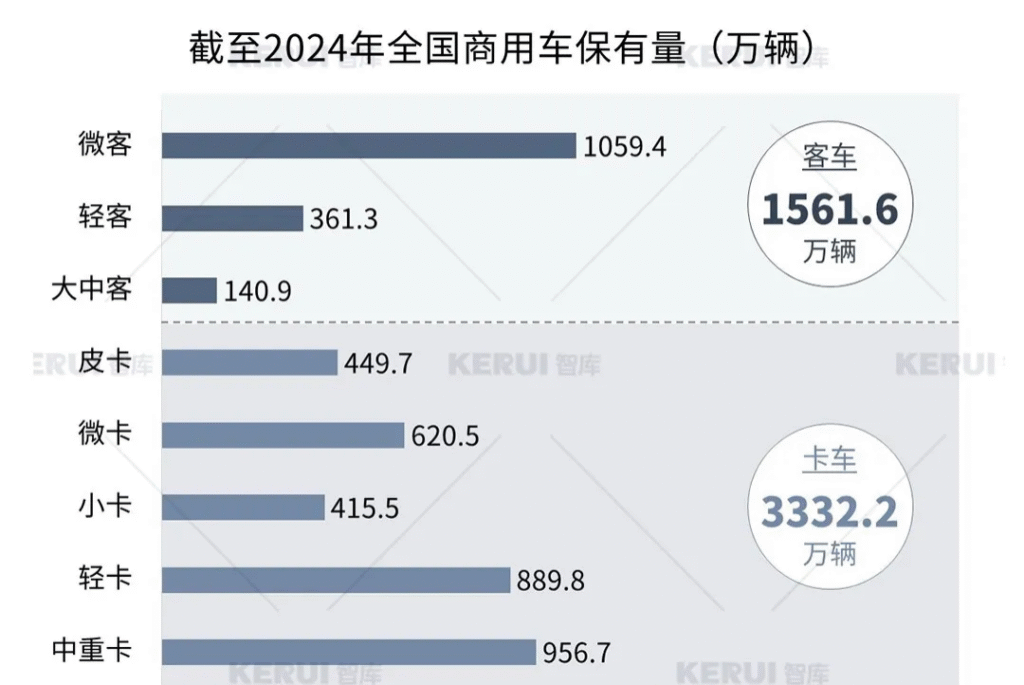

According to Kerui Consulting, estimates from 98% of the over 30 million fuel trucks in China still use lead-acid starting batteries. This power solution that has lasted for a century is facing double torture: the pollution threat of 500,000 tons of waste lead-acid batteries every year, and the high operation and maintenance costs caused by the average replacement cycle of 1.5 years. The lithium iron phosphate starting and parking integrated battery developed by TZST Lithium Battery is rewriting the rules of the industry.

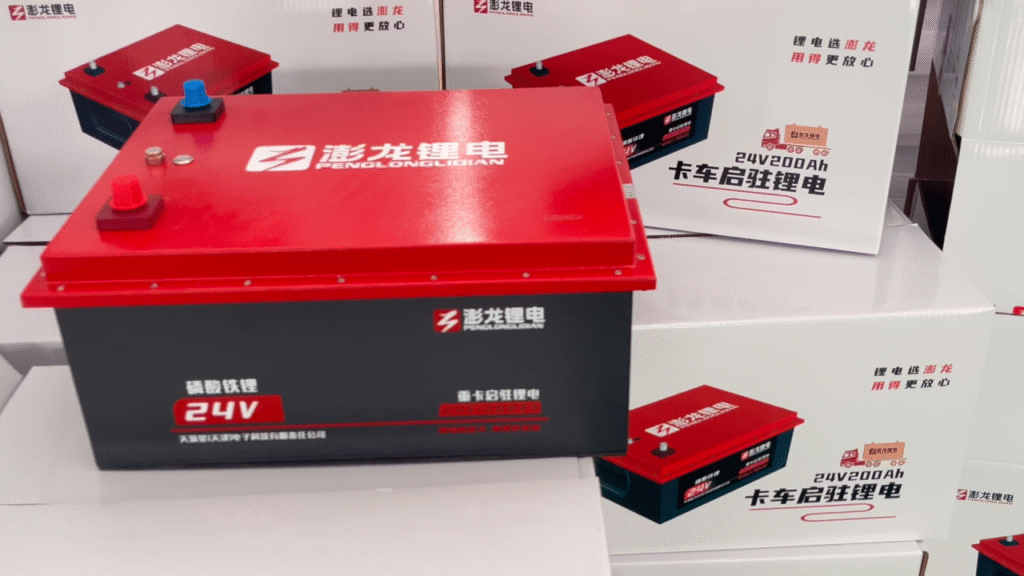

Behind the low-price advantage of lead-acid batteries are shocking hidden costs: the annual maintenance expenditure of replacing 1.5 sets of batteries for a single heavy truck, losing goods because of low-temperature strikes, the economic cost of lead-contaminated soil remediation… Industry estimates show that the replacement market potential of lithium iron phosphate starter batteries exceeds 300 billion yuan. TZST’s technology path directly addresses the pain points: its 24V200AH truck start-up lithium battery combines the start-up and parking power supply systems into one, reducing the size by 40% but providing twice the cycle life. In scenarios such as cold chain logistics and plateau transportation, the average annual fuel cost savings for a single vehicle exceeds 3,000 yuan. This transition from ” single function substitution ” to ” system value reconstruction ” is reshaping the underlying logic of commercial vehicle power economics.

The Mohe winter test in early 2025 became a concentrated demonstration of TZST’s technical strength: the 24V truck started with a lithium battery and was frozen outdoors at -40°C for 72 hours, and we successfully started the heavy truck three times in a row. Behind this “extreme stress test” is the full-link innovation of the material system: A+ grade lithium iron phosphate battery cell, 10C rate, instantaneous output power 3 times that of traditional batteries; the intelligent BMS system monitors the battery cell parameters in real time and controls the consistency deviation within the group within 3%. The simultaneous launch of the Mohe Service Station shows its “technology + service” two-wheel drive strategy – an all-round guarantee network built by service outlets across the country, allowing technological innovation to truly transform into user trust.

When the TZST truck used lithium batteries and roared steadily in the extreme cold of Mohe, this silent technological revolution has gone beyond the scope of product substitution. TZST Lithium Battery proves that the real industrial upgrade is not a crude subversion of the traditional path, but a systematic value reconstruction based on the pain points of the scenario. When more and more trucks start steadily on the winding highways of the Yunnan-Guizhou Plateau, and when countless drivers enjoy the coolness of parking air conditioners in the sweltering heat, this silent power revolution is writing a new footnote for the high-quality development of China’s logistics and transportation industry.