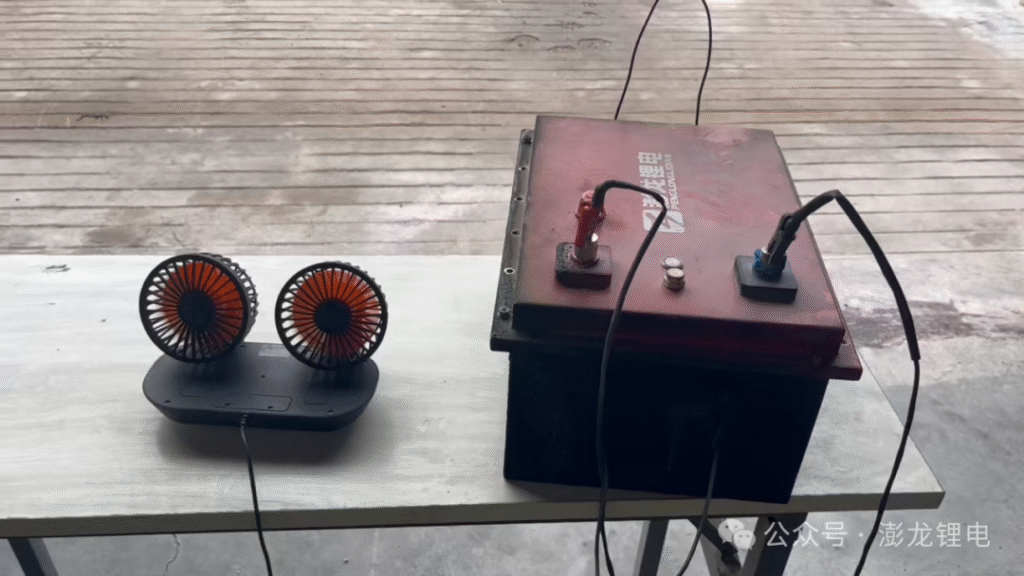

In mid-June 2025, TZST’s lithium battery quality team went to Tai’an, Shandong Province and conducted a very challenging lithium battery fire test at the national experimental base . This test conducted a 120 – second open flame direct combustion experiment on TZST truck‘s equipped with lithium-Ion batteries to verify the safety performance of the battery in extremely high-temperature environments.

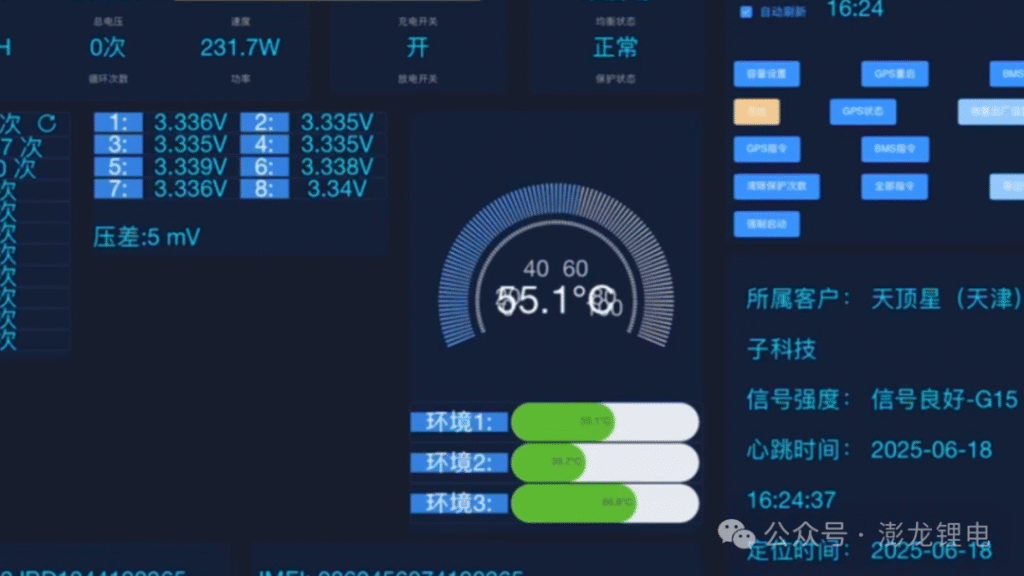

The test results are exciting: after 120 seconds of fire, the internal temperature of the battery is still stable within the normal operating range, and the BMS system operates normally, far exceeding the national standard of 70 seconds, fully demonstrating its excellent safety performance.

The partner for this test is Shandong Cathay Technology Co., Ltd. , a national high-tech enterprise integrating the scientific research and development, production and sales, construction and installation of fire protection products. The company is located at the foot of Mount Tai, the first of the five mountains, covering an area of 140 acres, with a factory building of 26,000 square meters and an office area of 7,000 square meters. It has professional fire protection equipment and fire experimental conditions . The TZST Lithium Battery team attaches great importance to product safety and participates in the entire experimental design to ensure the scientificity and reliability of the test.

TZST lithium battery ‘s outstanding performance in such a stringent fire test is inseparable from the support of its core technology. First of all , the outer shell is made of metal, and the interior is made of fireproof and heat-insulating materials, which can effectively blockconduction of high temperatures above 1300°C . Secondly , the BMS (battery management system) is equipped with 12 high-precision sensors to monitor and regulate the temperature of the battery core in real time to ensure thermal stability. In addition , the honeycomb structure design can effectively isolate the thermal runaway of a single battery core and prevent chain reactions. These technological innovations together form the safety moat of TZST Lithium Battery , allowing it to always maintain a leading position in the field of power batteries.

The person in charge said after the test: “Life is above all else, and quality is more important than Mount Tai. Safety has always been our first principle. Any improvement in performance cannot be at the expense of safety. ” TZST Lithium Battery has always regarded safety research and development as the core strategy of corporate development. It invests huge sums of money every year in technological innovation and safety verification , and strictly implements military-grade production standards to ensure that each battery has passed hundreds of rigorous tests . At present, TZST Lithium Battery has gone to various places to complete a number of cruel experiments , and its truck battery products have become the industry safety benchmark.

The success of the Taian fire test not only once again verified the safety and reliability of TZST lithium batteries, but also set a new technical benchmark for the industry. In the future, TZST Lithium Battery will continue to adhere to the concept of ” visible safety ” , promote the safety upgrade of the power battery industry with more transparent test data and stricter quality standards , and provide users with more secure and reliable products.